BMW Group — Highlights of my work as creative technologist.

Summary

My main role within BMW Group was to explore, iterate and validate design proposals early in the process of the concept car department. I often found myself with designers, artists, composers and engineers tinkering to make our ideas experience-able. I worked with various hard- and software tools such as Arduino, Kinect, Unity, MadMapper, Leap Motion, TouchDesigner and ProtoPie.

The process pictures are under NDA, so these are only the public visuals.

Supervisor

Daniel FischerWhat I worked on

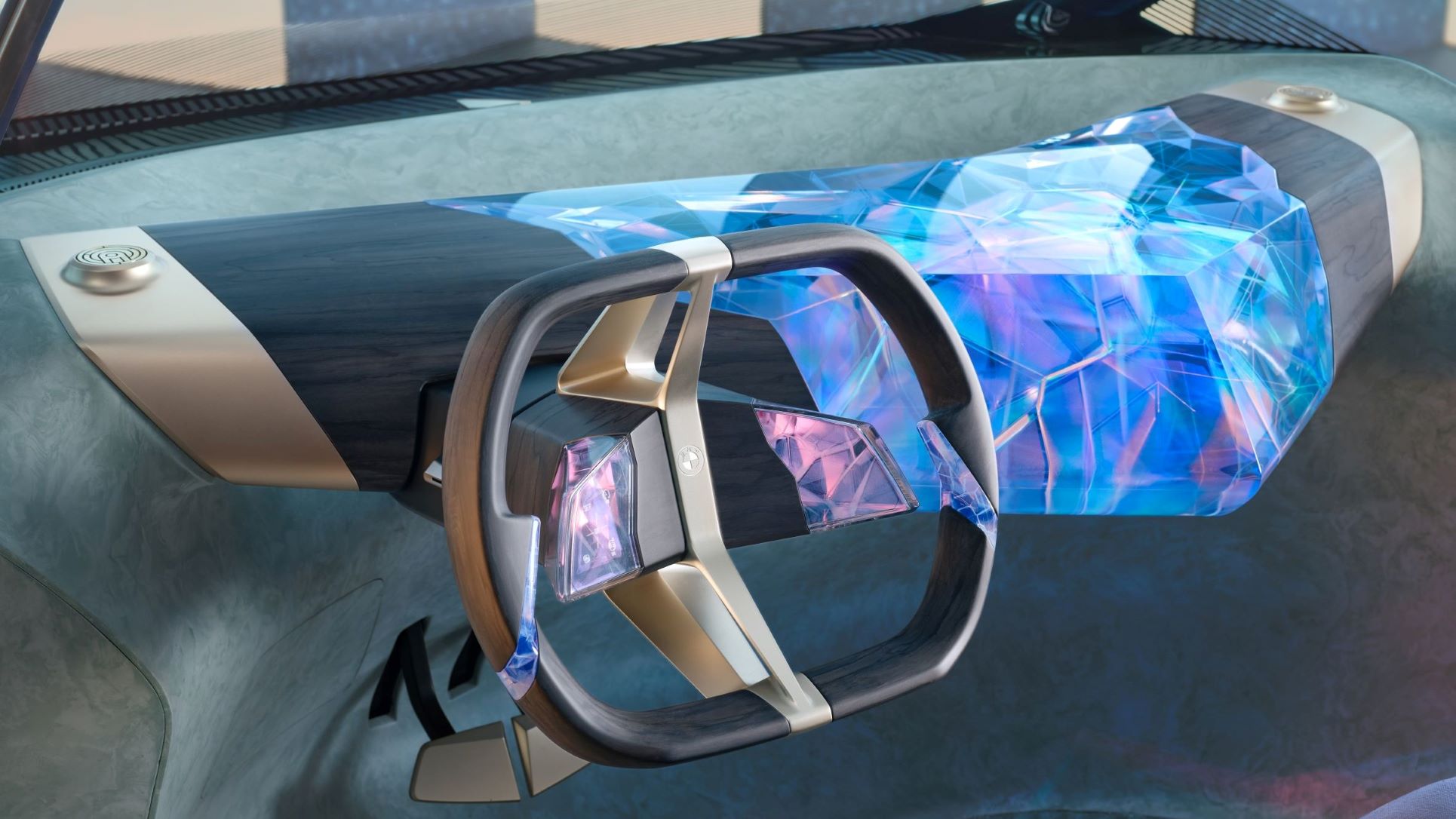

Dashboard animation

I was end responsible for the dashboard particle animation; initially I explored various ways of mapping light into the crystal and later, together with artists and composers, creating interactive animations in Unity VFX while integrating the gesture tracking of the engineering team. Low-fi mockups were made throughout the process using Leap Motion, Kinect and TouchDesigner.

Steering Wheel

The simplistic steering wheel raised many questions regarding interaction possibilities. I created interactive prototypes of the touchpads using Arduino and capacitive touch sensors which were directly integrated into ProtoPie so the design department could quickly try out and iterate on their UI and interaction concepts.

C-Pillar Lamps

The C-Pillar lamps are upcycled from old iDrive components. I received a sketch and turned that into an experience prototype using the original rotary encoder and crystal, an Arduino and a 3D printed enclosure. I created a PCB mockup, the swiveling mechanism and the (final) A-surfaces.

Art Bar

The Art Bar was something that was never done before, so we had to try how such component could function. I 3D printed the lower part of the Art Bar and made a mockup for the illuminated capacitive touch sensors and color recognition camera.

Free-form Hover Displays

Unfortunately, this project is still ongoing so I cannot share much, but throughout my internship I researched various technologies for free-form hover touch displays with the goal to easily and quickly explore display shapes and interactions in interior mockups.

image source: www.cnet.com/tech/mobile/touchless-touch-screen-gives-you-control-without-contact-video/

image source: www.cnet.com/tech/mobile/touchless-touch-screen-gives-you-control-without-contact-video/